Innovation as a driving force for progress

Geysen Robotics' service philosophy is based on working together with its customers. The study and definition of the company's technical problems is something that is carried out in a joint effort to ensure that the diagnosis is accurate and the solutions that are applied are immediately reflected in the profitability of the project.

Innovation, optimisation and experimentation are the raw materials with which our R&D department works. Its activity is focused on the detection of technological improvements and the creation of design projects in two main areas:

Robotics for product packaging.

Robotics for palletizing, packing and depalletizing of containers.

Our processes are internationally approved and fulfil all applicable standards for safety and efficiency.

Our success is our customers' success

We have worked this way for more than thirty years. A philosophy based on service that Geysen Robotics has implemented in all projects, in which we enjoyed the trust of the most important companies in the Spanish agro-industrial sector.

And so it will be in the future, because the future starts now.

Our professionals have the most advanced tools to help you with your projects:

Design

Design using CAD 3D software. You will be able to see, examine and interact with every element of your project, because every detail is important.

Analysis and simulation

Analysis and computational simulation (CAE). This allows us to know the behaviour of each part before its manufacture, which translates into less waste and therefore lower economic costs.

Manufacturing

Manufacturing using CAM applications. Thanks to the use of CNC machine tools, we achieve maximum precision and performance parts.

Space

More than 3,000m² where each project can be implemented and tested.

Examples of R&D projects currently in progress

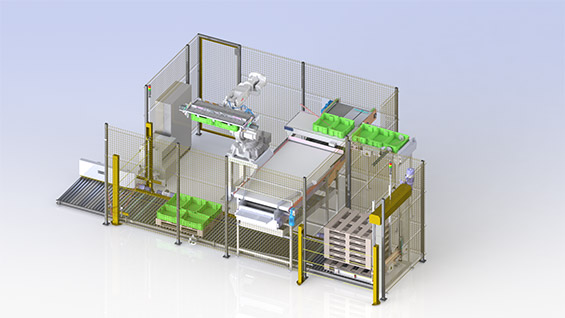

Robotic case packer mod. “RCP-22”

Project developed together with our client SAT CAMPOS DE GRANADA (Carchuna, Granada) in which we solved the need to automate the process of packing baskets, trays and tubs of cherry tomatoes for shipping.

Depalletizing and tipping “DPVG20-CHERRY”

This project required the automation of the depalletization process of plastic crates and later tipping to feed the packaging line with a very high production. The tomatoes must be tipped very delicately in order to maintain its qualities.