Latest projects

S.A.T. Bio Sabor

Bio Sabor is a company defined by "a constant search for differentiation based on innovation, as a company committed to the environment, health and sustainability".

- Implementation: Global

- Location: Campo de Níjar, Almería

- Enterprise: S.A.T. Bio Sabor

Start

In 2018, Bio Sabor started up a new processing centre in Campo de Níjar (South-East Almeria). The most advanced equipment, a highly automated process designed specifically for the tomato varieties they produce.

Evolution

To carry out this complex engineering development, study and installation of all the equipment in its production chain, Bio Sabor relied on the experience of Geysen Robotics. The success of the solutions applied, endorses this decision.

Solution

Geysen Robotics developed a scalable project. The entire system is prepared to respond to continuous growth, providing the entire facility with maximum reliability in the face of ever-increasing product volumes.

The most advanced facilities in the sector

The Bio Sabor facilities are among the most advanced in the entire fruit and vegetable sector and a benchmark in the area. For Geysen Robotics it was a great professional challenge and it was also a great success, as it was overcome thanks to the close work carried out with our client. A project we feel part of.

Objectives achieved

- Care for products quality.

- Improve working conditions.

- Optimisation of the physical space available.

- Make the production process results profitable.

Solutions applied

- Handling and packaging lines with the most sophisticated control, safety and automation systems on the market.

- Packaging logistics for storage and delivery with different levels of crate traffic.

- Depalletized robots.

- Robot depalletizer-tipping for cherry tomatoes. Unique on the market.

- Automated incoming and outgoing pallet lines.

- Automatic entry line destackers.

MABE

MABE currently has a 25,000 m² warehouse and facilities that are considered to be among the most advanced and modern for reception, handling and packaging in the sector. Fully air-conditioned facilities, with facial control for personnel access, automatic control of traceability and, of course, machinery that allows us to be more agile, efficient and competitive.

- Implementation: Global

- Location: Las Norias de Daza, West Almería.

- Enterprise: MABE S.A.T.

Start

In 2019 MABE wanted to count on Geysen Robotics for the latest expansion of its facilities, as on previous occasions, to take on a very ambitious technological challenge: tripling production.

Evolution

This company works with more than 10 varieties of vegetables with their own characteristics. From big watermelons to small peppers, the only thing they have in common is that they must be treated with extra care.

Solution

Geysen Robotics approached the design and implementation of the equipment, applying the highest quality standards and providing advanced technical solutions to meet the proposed objectives.

One of the biggest technological challenges

This has been one of the biggest technological challenges faced by Geysen Robotics. The result has led to significant improvements in our customer's bottom line in terms of productivity and profitability. A great success of which we are extremely proud.

Solutions applied

- Automated incoming and outgoing pallet lines.

- High-capacity robotic depalletizing.

- High-performance crates tipping.

- Product washing and drying.

- Sectorised container logistics, with circuits on different levels.

- Packaging storage mezzanine.

- Palletization of crates.

- Automatic filling of product crates.

SUREXPORT

At Surexport we are committed to producing berries of the highest quality. That is why we are firmly committed to research and development in order to achieve fresh, healthy, nutritious and tasty products. We specialise in strawberry, raspberry, blueberry and blackberry.

- Implementation: Global

- Location: Almonte, Huelva

- Enterprise: SUREXPORT Compañía Agraria, S.L

Start

Surexport aims to improve its productivity by optimising handling lines and automating flows in its packaging logistics, while modernising its entire global process. Geysen Robotics has been chosen for this purpose.

Evolution

Surexport is a benchmark in a type of product that presents great technical challenges in its handling process: processes cannot exceed 48 hours, maximum care for highly perishable products, and strict quality controls.

Solution

This project is a challenge for Geysen Robotics in terms of developing specific solutions for a very special sector such as berry handling. For this reason, a thorough study of needs with engineering solutions is proposed.

Exceeding expectations

The result of this performance has far exceeded the initial expectations of Surexport's management team. A triumph achieved by working together, innovatively and ambitiously, which shows that our success is always the success of our customers.

Solutions applied

- Modular circular belt lines, for a continuous flow of tubs, in linear and continuous production.

- Automatic vertical unstacking system for crates, adapted to the available space.

- Depalletizing robots with adaptive grippers for special crates.

- Sectorized packaging logistics by means of conveyors on different levels.

- Global process automation.

- Enabling connections and peripherals for Industry 4.0 implementation.

CoopHuelva

Producers and marketers of berries for more than 35 years the Sociedad Cooperativa Andaluza Costa de Huelva (Coophuelva) is a berry distribution company with a strong social economy character, dedicated for four decades to the marketing of its members' agricultural produce.

- Implementation: Global

- Location: Almonte, Huelva.

- Enterprise: Costa de Huelva S.C.A.

Start

This cooperative began its activity with the commercialization of strawberries and over time it has greatly diversified its offer by incorporating new varieties until it has become one of the main berry distribution companies at regional and national level.

Evolution

As part of this policy of improvement and expansion, a new handling and packaging centre was set up in Valdeoscuro in 2021. Its technical design and implementation have been one of the most challenging projects that Geysen Robotics has faced.

Solution

We implemented highly innovative solutions to achieve the company's ambitious goals: The processing of no less than 180 tonnes of blueberries and 100 tonnes of strawberries per day at the highest product quality level.

New solutions were required

It was one of the most complex projects developed by Geysen Robotics in recent years and was also completed in record time. It was necessary to imagine new solutions that were able to meet the demands of a market sector in which product care must be of the utmost importance.

Solutions applied

- Sectorized packaging conveyor circuits: infeed and outfeed.

- High capacity Cartesian depalletizers with adapted design.

- High capacity Cartesian palletizers.

- Multi-level production lines, COVID safety systems, ergonomics and production controls per workstation.

- Output transfer lines: scale and strapping machine.

- Input transfer lines: scale.

- Automated crate stacking.

- Global process automation.

GRUPOLUCAS

At Group Lucas we have a strong commitment to society and the environment, we are driven by the desire to improve, to make our products quality better every day.

- Implementation: Global

- Location: Raal, Murcia.

- Enterprise: Agrupación Hortofrutícula Lucas OPFH SL

Start

Grupo Lucas is a company that is constantly growing and is currently one of the leading fresh products companies in Spain. Its flagship is quality and it has traditionally been a company that has been committed to innovation as a driving force for development.

Evolution

In 2022, Grupo Lucas decided to solve one of its biggest packaging problems: the polystyrene boxes containing the fresh product were very fragile, preventing them from being automated and consequently slowing down the production flow.

Solution

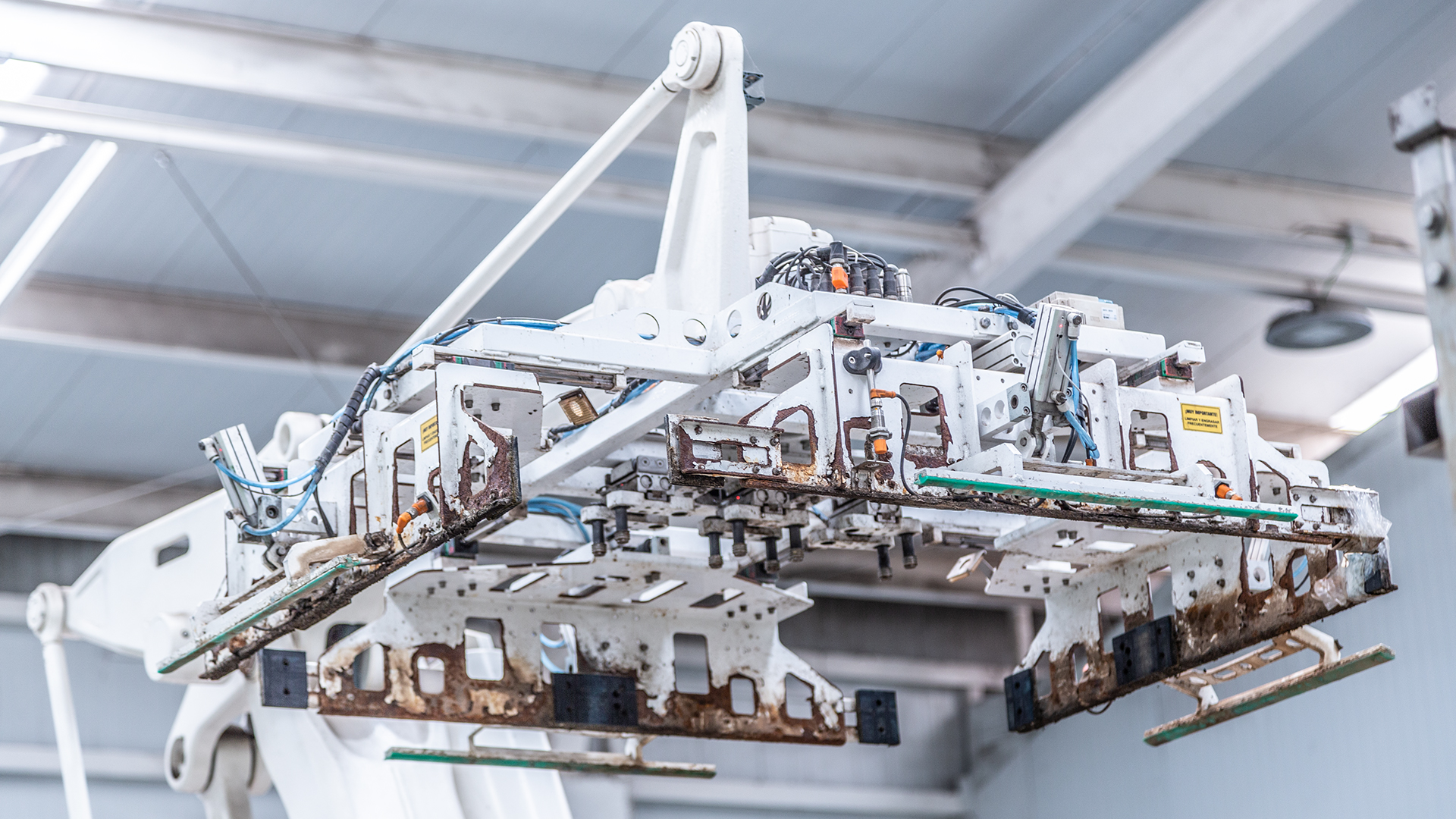

We developed robotic cells to automatically depalletize pallets of polystyrene boxes, without fractures, by means of adaptive grippers on the robot head, which had a special quality: controlled closing pressure, able to handle the mosaics safely without damaging the packaging.

One of the most specific developments

This has been one of the most specific developments we have dealt with in recent times, an installation that is still underway and which will be completed by the end of this year with the implementation of the 4 robotic cells that make up the entire project.

Solutions applied

- Sectorized packaging conveyor circuits: infeed and outfeed.

- High capacity Cartesian depalletizers with adapted design.

- High capacity Cartesian palletizers.

- Multi-level production lines, COVID safety systems, ergonomics and production controls per workstation.

- Output transfer lines: scale and strapping machine.

- Input transfer lines: scale.

- Automated crate stacking.

- Global process automation.